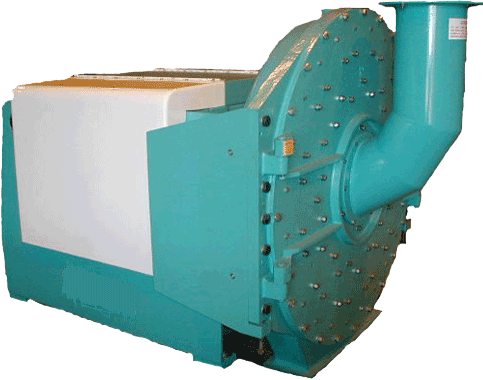

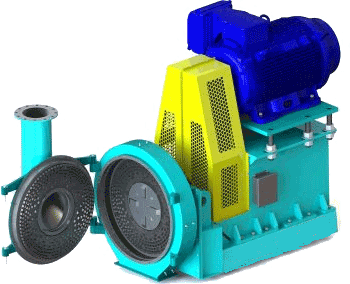

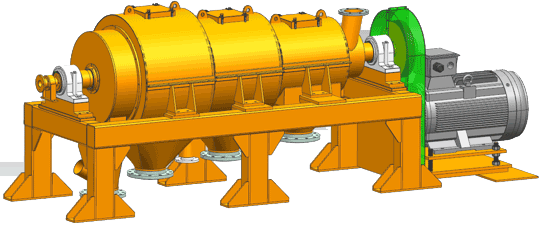

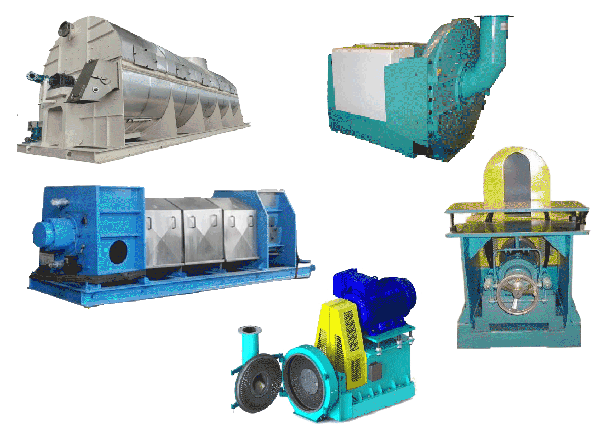

Changchun SHENG Machinery Manufacturing Co.,Ltd. A leading company in the research and development of drying and dehydration technology, dedicated to provide customers with corn fiber, germ, protein and alcohol DDGS dehydration and drying full range of technical advice, research and development, design, production, installation and commissioning services. Industry involved in food, chemical, pharmaceutical, sewage treatment and other fields. With over 26 years' experience in the key equipment of corn wet milling starch industry, we can provide all-round technical consultation, R & D, design and manufacture. Changchun SHENG company is one of the professional manufacturer for tube bundle dryers and screw presses in China. The company introduces the world's most advanced welding robot to carry out the welding of the core tube bundle of the dryer, the company has advanced machining center CNC Machine Tools, a variety of professional machine tools, a variety of welding equipment, CNC cutting equipment several. The company has the most professional drying, dehydration, wet grinding design and service team, can provide customers with the perfect solutions.